TEAM HENLE

HENLE is a family owned and managed company located in Rammingen, southern Germany. The company is currently led by the second generation, while the third generation has been working in the company for several years now too. Yet even though this company comes from a small Swabian village, it sells quality products on an international basis! HENLE can both supply and advise loyal customers located in other European countries as well as closely works together with partners and suppliers from all over the world with a strong team of qualified staff members.

HENLE HISTORY

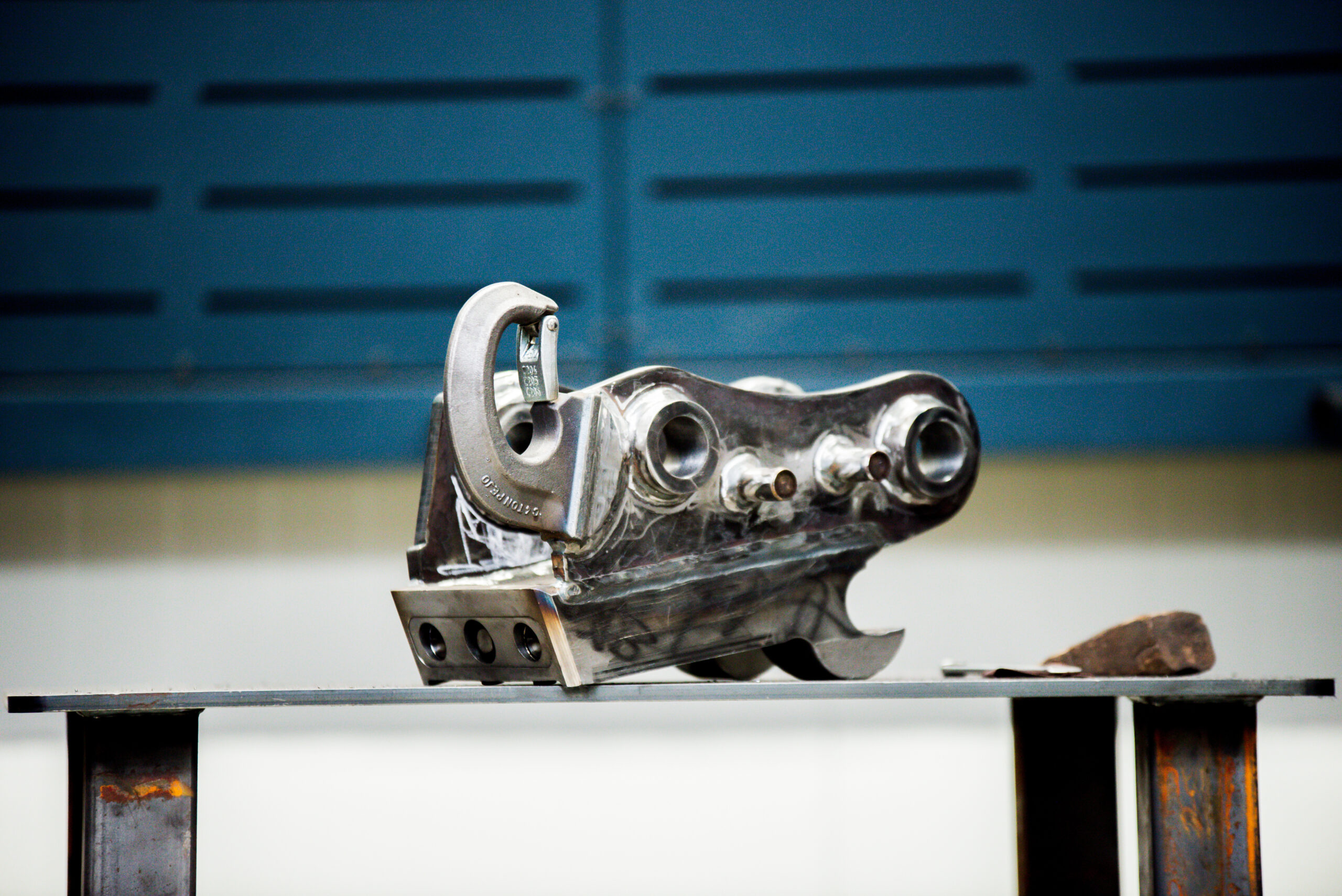

HENLE Baumaschinentechnik GmbH was founded in 1981 by Werner Henle, who fulfilled his wish to set up his own business with his wife, Irene. Together, they laid the foundation stone for a company that more than 35 years later is now one of the market leaders in the field of attachments for compact machines in the German market!

HENLE has remained an owner-managed family company throughout its history and has remained loyal to its headquarters in Rammingen, Swabia. The HENLE Team has now grown to over 100 members, including the grandchildren of the founding couple, who work in the company together with Gerhard and Gabriele Henle. Over the years, HENLE has developed from a small steel construction company into a medium-sized industrial company that deliberately concentrates its production at the original location in Rammingen.

HENLE HISTORY

HENLE MISSION STATEMENT

Our daily actions are built upon a value-based philosophy. We believe our values are the key to us being and remaining both healthy and successful as a company.

COMPANY

With our name, we stand for fair treatment of our customers and our suppliers.

Our employees form the indispensable basis on which we can live up to our principles of quality and performance. Environmentally friendly business is an obligation for us.

As a family-owned company, we take our social responsibility towards the region and society seriously.

CUSTOMERS

The customer is our future. We pursue the goal of maintaining long-term and cooperative business relationships with our customers and delivering consistently high quality to the extent commissioned and promised. We prepare our offers quickly, in detail and transparently. In this way, we define the unambiguous entitlement to benefits at an early stage.

We see complaints as our opportunity to improve our work. We live the service concept with conviction, conduct open, honest communication with the customer and provide him with contact persons with a high level of professional and social competence.

TOGETHERNESS

Our employees are our capital. We offer our employees long-term and secure jobs under good and fair working conditions and strive for a high level of identification among employees with the company. We promote this through regular training and further education, the provision of high-quality equipment and materials, and the transfer of the highest possible level of personal responsibility to each employee.

The basis for the cooperation of our employees is mutual trust, recognition and appreciation of the individual. We promote the development of the personality of our employees and the activation of their personal resources.

SUSTAINABILITY

As a personnel-intensive company, we face up to our social responsibility in creating and maintaining jobs and apprenticeships.

In the company, we pay attention to the preservation of social peace and social justice and the protection of the human dignity of every employee.

We live up to our social responsibility towards our employees and their families to the highest possible extent.

When dealing with operating materials and energy, we pay attention to environmental compatibility and economic efficiency.

SUPPLIERS

We see our suppliers first and foremost as business partners, whose reliability, quality and loyalty we treat with tolerance and fair dealings.

We only demand what is feasible from our suppliers, but we do so permanently and reliably.

Our suppliers are long-term partners of our company. We work together to solve problems and further develop products.

FUTURE

We work for the future.

In doing so, we draw on our tradition and promote the innovative strength of our employees. We plan for the long term.

As a result, we are well equipped for the future – with modern structures and technologies that can also prove themselves in relation to future challenges.

In the cross-generational team, we grow together and can gain strength.